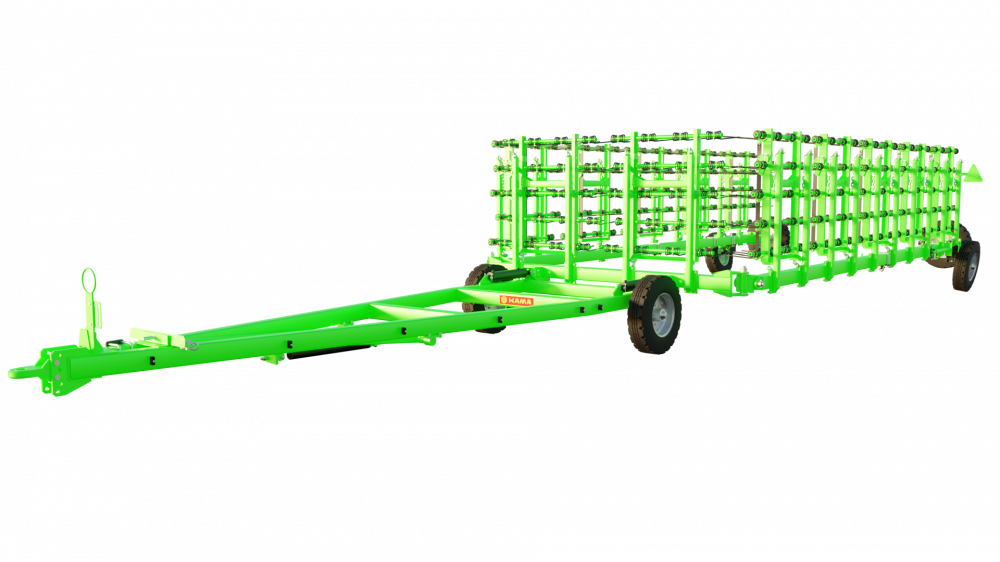

KAMA PANTHER-18 MEDIUM SPRING HARROW (STUBBLE)

| Width is : | 4.5 m. |

| Height is : | 2.2 m. |

| length is: | 14.4 m. |

| Weight is : | 3050 kg. |

| Цена | от 1 316 300 rub.* |

specifications

|

General specifications |

Dimensions in operation position |

||

| Capacity is: | 27,4 ha/h | Tillage area width is: | 18,4 m |

| Weight is | 3050 kg | Height is | 1,1 m |

| Hydraulic cylinders | 2 pairs | Length is | 8,6 m |

|

Dimensions in position |

Working teeth are | 240 pcs | |

| Width is: | 4,5 m | Tooth diameter is | 10 m |

| Height is | 2,2 m | Tillage area depth is up | To 6 cm |

| Length is | 14.4 m | Width between teeth on the track is | 34 mm |

| Angle of contact of the teeth is | 400 degrees | ||

| The required tractor power is | 130-150 h.p. | ||

Description

The harrowing is carried out by trailed sections of the harrow with spring teeth.

The uneven resistance of the soil to movement of the harrow teeth during operation creates teeth vibration with a variable and unequal frequency and amplitude for each tooth, so that's why the soil is loosened better, weeds are destroyed more efficiently.

The harrow sections are suspended on flexible elements (chains), so the harrow teeth under the influence of soil resistance forces fluctuate in the vertical and horizontal plane, which increases the area of impact of the tooth on the soil.

The flexible suspension of the harrow sections and their small width ensure good soil gauging.

The tool is less subject to clogging with weeds and plant debris due to high position of the harrow bars above the soil.

It should be also noted that the harrow is quickly moved from the transport position to the working position and back, as well as it is possible to quickly lift the sections before turns and for cleaning the sections.

In the working position, the sections are lowered to the ground, the side bars are deployed frontally, the running wheels are supported by the ground, the transport wheels are raised.

In the transport position, the sections are raised by turning the bars, which are fixed by the hydraulic cylinder retainers from reverse rotation.

The side bars are rolled back and fixed with a safety rope (chain) from diverging over the size of 4.4 m.

The running wheels are raised, and the transport wheels rest on the ground.

The degree of loosening of the soil to the required depth or mode of harrowing of cultivated crops is performed by mechanism of changing the angles of inclination of the spring teeth.

Reducing the angle of inclination of the teeth makes it possible to reduce the mixing of the soil, to better clean the harrow from debris, to less intensively affect the cultivated crops.

Increasing the angle of inclination of the teeth makes it possible to strengthen the harrowing process.

The main components of the structure are made of 09G2S steel.

The machinery is delivered semi-assembled (hardware products are folded into a box of spare parts and accessories).Purpose:

- Field alignment

- Mulching before sowing of grain and industrial crops

- Destruction of weeds in the white thread phase

- Pre-emergence and post-emergence harrowing

- Filling of mineral fertilizers

- Preparation of seedbed.

We cooperate with companies from the Russian Federation and the CIS

Documents

IMPORTANT!

- Information on the technical characteristics of goods indicated on the site can be changed by the manufacturer unilaterally.

- Images of goods in the photographs presented in the catalog on the site may differ slightly from the originals.

- Information on the price of a product indicated in the catalog on the website may differ from the actual one at the time of placing an order for the relevant product.

*Prices are indicated taking into account discounts under a price program from the manufacturer. The prices listed are for informational purposes and are not an offer. The quantity of goods is limited. Please check with the sales department for more details +7 (8552) 20-20-71